Welcome to Swastik Engineering Works

Swastik Engineering Works are maintaining high quality products with the brand name of Tiger manufacturing various types of instrumentation hardware fittings. With more than four decades experience, we believe in continuously improving our products and services. So that customers requirements for safety and performance are satisfied under the brand name of Tiger.

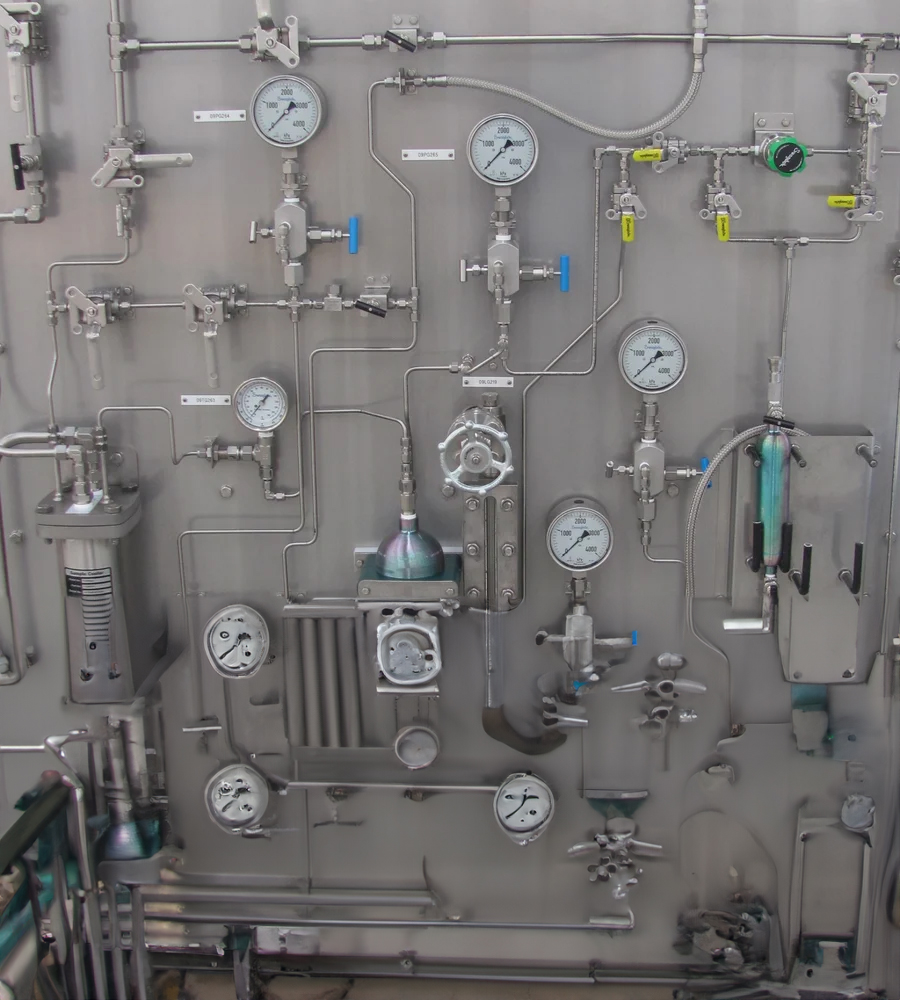

The reputation we enjoy for the excellence of design, material and workmanship of our product is the result of hard labor and careful study of the exact requirement of the various industries in the class of goods in which we are working. Tiger Valves & Fittings are designed to withstand high-pressure service and are capable to satisfy various stringent tests like Pressure impulse, Vibration test, Vacuum test, Temperature cycle test, make & Remake test etc. as per BS 4368 Part IV at our in house testing facilities. The above tests have been periodically witnessed by various inspection agencies / consultants like, EIL, DNV, LRIS, BVQI, ONGC, BARC, UDHE, TOYO to name few.

In today modern world, applications are wide and that include Nuclear Power Plants, Refineries, Petrochemicals, Fertilizers, Thermal Power stations and may more and to meet their specific requirements, we are always trying to improve quality of the products with quality consciousness. We shall, at all time welcome a suggestion from any customer present or prospective, who could help us in bringing our products to their fullest satisfaction to give Tiger valves the stamp of guarantee. Tiger Fittings and Valves are available in variety of construction material ranging from SS (low carbon also), C.S. Monel, and Brass material are tested at reputed Government approved laboratories confirming to ASTM, ANSI, IS etc. standards.